Effluent Treatment Plant (ETP) Design & Installation

Turnkey ETP solutions that combine advanced physio-chemical treatment with tertiary polishing to remove heavy metals, oil & grease, and suspended solids while ensuring strict regulatory compliance.

100% Compliance

Ultra-robust industrial wastewater treatment customized per sector

Zero Liquid Discharge

Advanced physio-chemical + tertiary polishing train for compliance-ready discharge

24/7 Support

Lifecycle partnership with treatability studies, training, and AMC support

Ultra-robust industrial wastewater treatment customized per sector

Service overview

Effluent Treatment Plants (ETPs) are engineered to treat industrial wastewater from manufacturing, chemical, textile, pharmaceutical and similar facilities before discharge. These effluents often carry harmful chemicals, oils, grease, and suspended solids that must be removed through integrated physical, chemical, and biological processes to meet pollution norms.

We deliver complete ETP design, planning, and installation tailored to wastewater type and volume. Using advanced aeration, clarification, filtration, and sludge management technologies, each system is customized to control operating cost, reduce environmental impact, and comply with CPCB/SPCB standards.

Deployment Scope

Industrial clusters, Hospitals, Restaurants, Dairy plants

Key Advantages

Environmental compliance ensured, Optimized energy and chemical footprint, Future-ready automation and controls, Custom engineering for every site

Highlights

Regulatory ready • AI assisted monitoring • High uptime assurance

proof of value

Engineered for performance & scale

Key Features

- End-to-end EPC delivery

- Advanced physio-chemical treatment

- Tertiary polishing and disinfection

- Heavy metal & oil removal

- 24/7 remote monitoring

- Performance guarantees

Where It Fits

- Industrial clusters

- Hospitals

- Restaurants

- Dairy plants

- Manufacturing units

Business Wins

- Environmental compliance ensured

- Optimized energy and chemical footprint

- Future-ready automation and controls

- Custom engineering for every site

- Dedicated service and AMC plans

Launch Checklist

- Regulatory ready

- AI assisted monitoring

- High uptime assurance

What you get

Deliverables bundled with every deployment

We package each project with tangible artefacts so your engineering, finance, and compliance teams never chase updates. Every deliverable is documented, versioned, and shared in a digital locker for easy recall.

Treatability & design basis

Composite sampling, BOD/COD profiling, and regulatory benchmarking that lock the process parameters.

Detailed engineering pack

Civil GADs, hydraulic calculations, P&IDs, dosing charts, and electrical load schedules ready for execution.

Fabricated process modules

Clarifiers, aeration skids, tertiary filters, MCC panels, and automation hardware manufactured & QA tested.

Compliance & operations kit

SOPs, log sheets, consent documentation support, and operator training video walkthroughs.

Engagement playbook

Exactly how we run the mandate

Crystal-clear SLAs keep every stakeholder aligned. From sample collection to AMC handover, we spell out the response times, documentation, and escalation layers in writing.

Kickoff Sprint

Samples captured + design discovery workshop within 5 business days of project confirmation.

Deployment Window

8–12 week EPC window covering fabrication, dispatch, mechanical erection, and commissioning.

Compliance Assurance

CPCB/SPCB compliance dossier, performance testing, and third-party lab validation included by default.

Support Model

24/7 command center, remote instrumentation checks, and AMC-ready service teams with spare inventory.

delivery blueprint

How your project comes alive

Influent sampling & treatability study

Influent sampling & treatability study

Custom process design & engineering

Custom process design & engineering

Fabrication, procurement & logistics

Fabrication, procurement & logistics

On-site installation & integration

On-site installation & integration

Commissioning with performance run

Commissioning with performance run

Operator handover with training

Operator handover with training

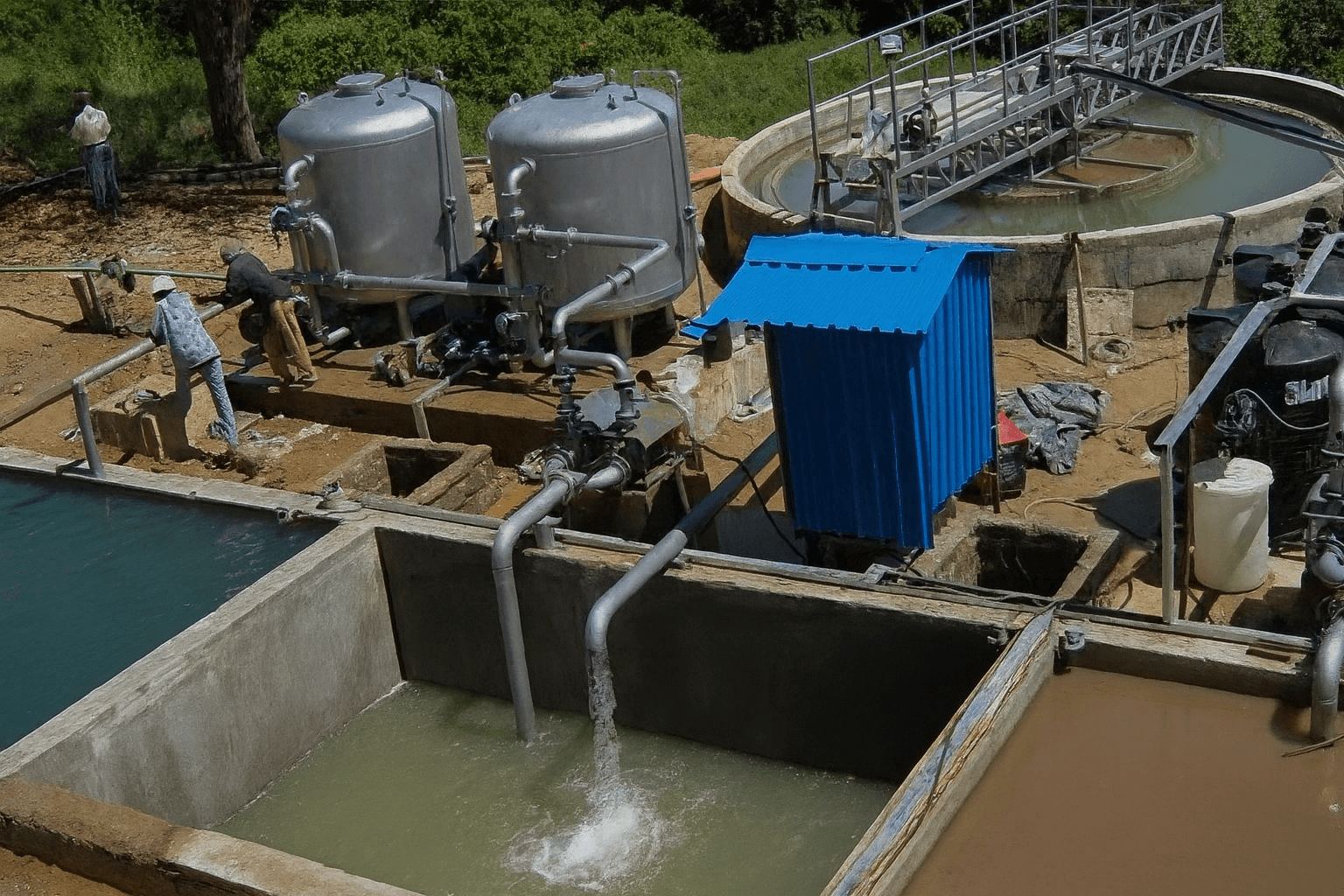

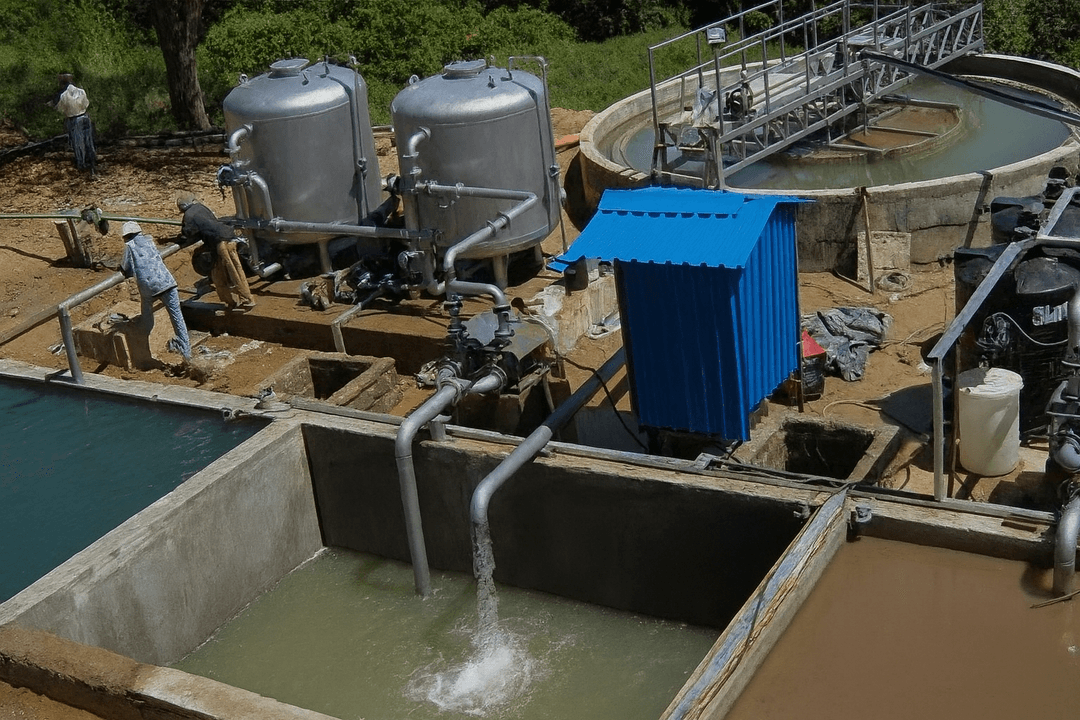

live installs

Snapshots from recent deployments

Click to view full size

Common Questions

Frequently Asked Questions

An Effluent Treatment Plant (ETP) treats industrial wastewater before discharge. It's mandatory for industries to comply with pollution control board regulations and protect the environment.

Ready to Get Started?

Contact us today for a free consultation and customized solution for your environmental needs.