Reverse Osmosis (RO) & Water Purification Systems

High-recovery RO & purification systems engineered for industrial, commercial and institutional use with comprehensive membrane analytics, chemical support and proactive maintenance.

High Recovery

High-recovery RO lines for industrial, commercial, and institutional use cases

Multi-Stage

Hybrid purification stacks combining membrane, UV, ozone, and carbon filters

24/7 Monitoring

Continuous monitoring, membrane analytics, and chemical support programs

High-recovery RO lines for industrial, commercial, and institutional use cases

Service overview

Reverse Osmosis and purification systems generate clean, safe water by forcing feed water through semi-permeable membranes that remove dissolved salts, hardness, bacteria, and impurities.

We design and install industrial, commercial, and domestic RO plants with multi-barrier setups that can include membrane filtration, UV, ozone, and carbon modules. Every plant is sized to local water chemistry, remains energy-efficient, easy to operate, and consistently delivers high-quality output.

Deployment Scope

Industrial process water, Schools & colleges, Hotels, Hospitals

Key Advantages

Consistent potable quality, Lower membrane fouling rates, Bundled chemical program, Nationwide service network

Highlights

Membrane autopsy support • Chemicals + service bundle • ATM ready formats

proof of value

Engineered for performance & scale

Key Features

- High recovery membranes

- Intelligent CIP routines

- Real-time TDS tracking

- Multi-barrier filtration

- Customized skids and kiosks

- 24/7 remote support

Where It Fits

- Industrial process water

- Schools & colleges

- Hotels

- Hospitals

- Rural water ATMs

Business Wins

- Consistent potable quality

- Lower membrane fouling rates

- Bundled chemical program

- Nationwide service network

- Flexible financing options

Launch Checklist

- Membrane autopsy support

- Chemicals + service bundle

- ATM ready formats

What you get

Deliverables bundled with every deployment

We package each project with tangible artefacts so your engineering, finance, and compliance teams never chase updates. Every deliverable is documented, versioned, and shared in a digital locker for easy recall.

Feed water audit + projection

TDS, silica, hardness, and SDI profiling with recovery projections so stakeholders see the payback instantly.

Skid & kiosk engineering pack

3D layouts, mechanical GA, electrical SLDs, membrane loading plan, and plumbing schematics for civil coordination.

Multi-barrier purification stack

RO membranes, media filters, UV/ozone, dosing systems, pumps, and control panels fabricated with FAT videos.

Operations playbook

CIP routines, membrane health tracker, chemical MSDS, and preventive maintenance checklists.

Engagement playbook

Exactly how we run the mandate

Crystal-clear SLAs keep every stakeholder aligned. From sample collection to AMC handover, we spell out the response times, documentation, and escalation layers in writing.

Kickoff Sprint

Water sampling + sizing workshop within 72 hours for rapid budgeting.

Deployment Window

4–8 week delivery depending on capacity, including FAT, dispatch, and on-site commissioning.

Compliance Assurance

Performance guarantee on permeate quality with rejection tuning, testing, and documentation.

Support Model

Membrane analytics, chemical supply integration, and hotline support with SLA-backed service visits.

delivery blueprint

How your project comes alive

Source water audit

Source water audit

Membrane & skid sizing

Membrane & skid sizing

Factory assembly & FAT

Factory assembly & FAT

On-site installation

On-site installation

Commissioning & training

Commissioning & training

Continuous monitoring

Continuous monitoring

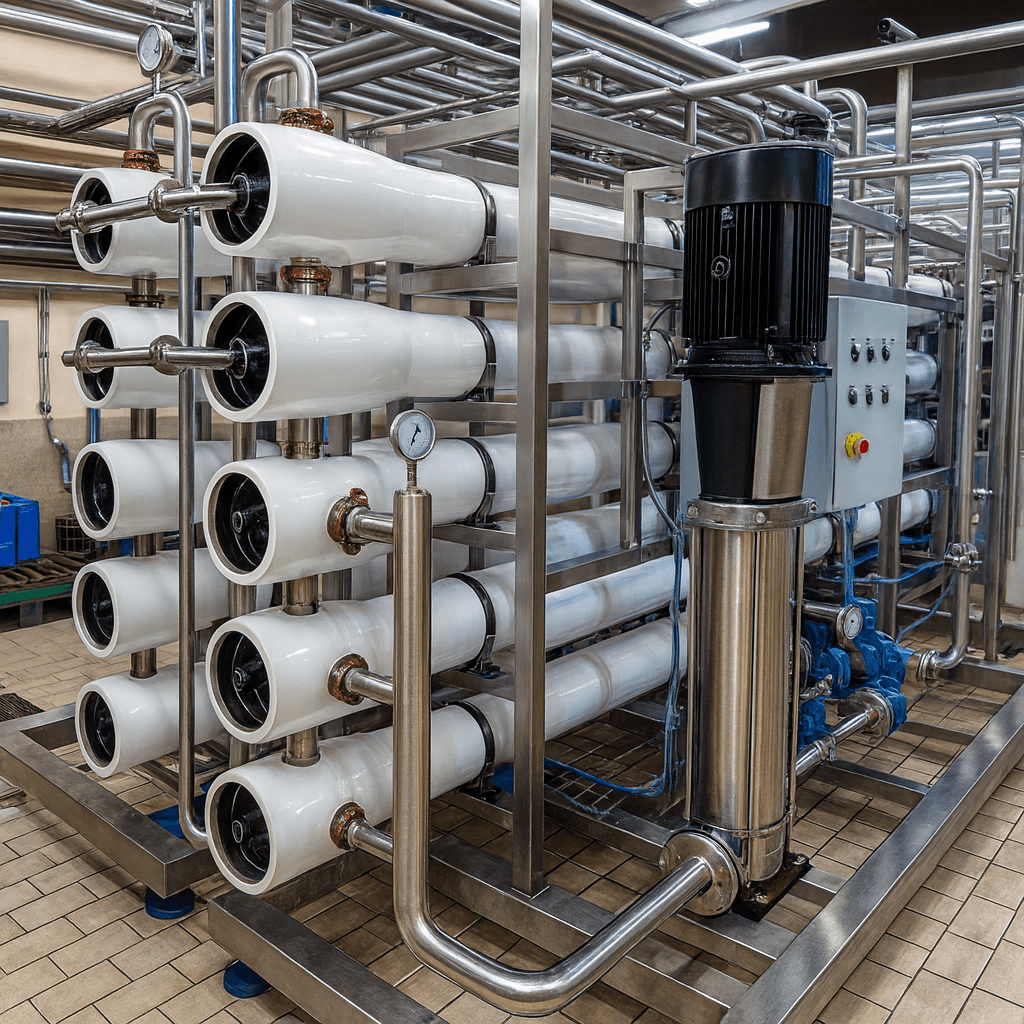

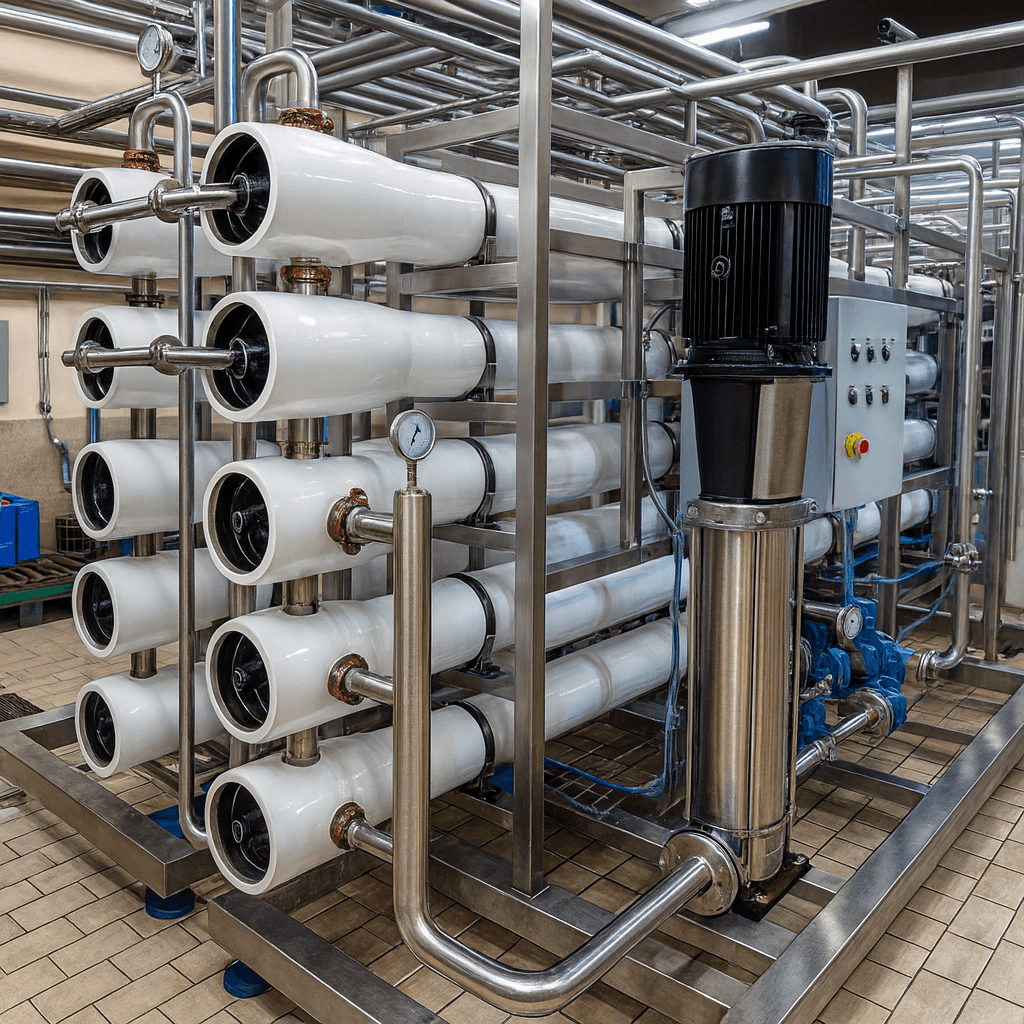

live installs

Snapshots from recent deployments

Click to view full size

Common Questions

Frequently Asked Questions

RO membranes typically last 2-3 years with proper maintenance. Regular cleaning, pre-filtration, and chemical treatment can extend membrane life significantly.

Ready to Get Started?

Contact us today for a free consultation and customized solution for your environmental needs.

%20water%20treatment%20plant.jpg&w=3840&q=75)