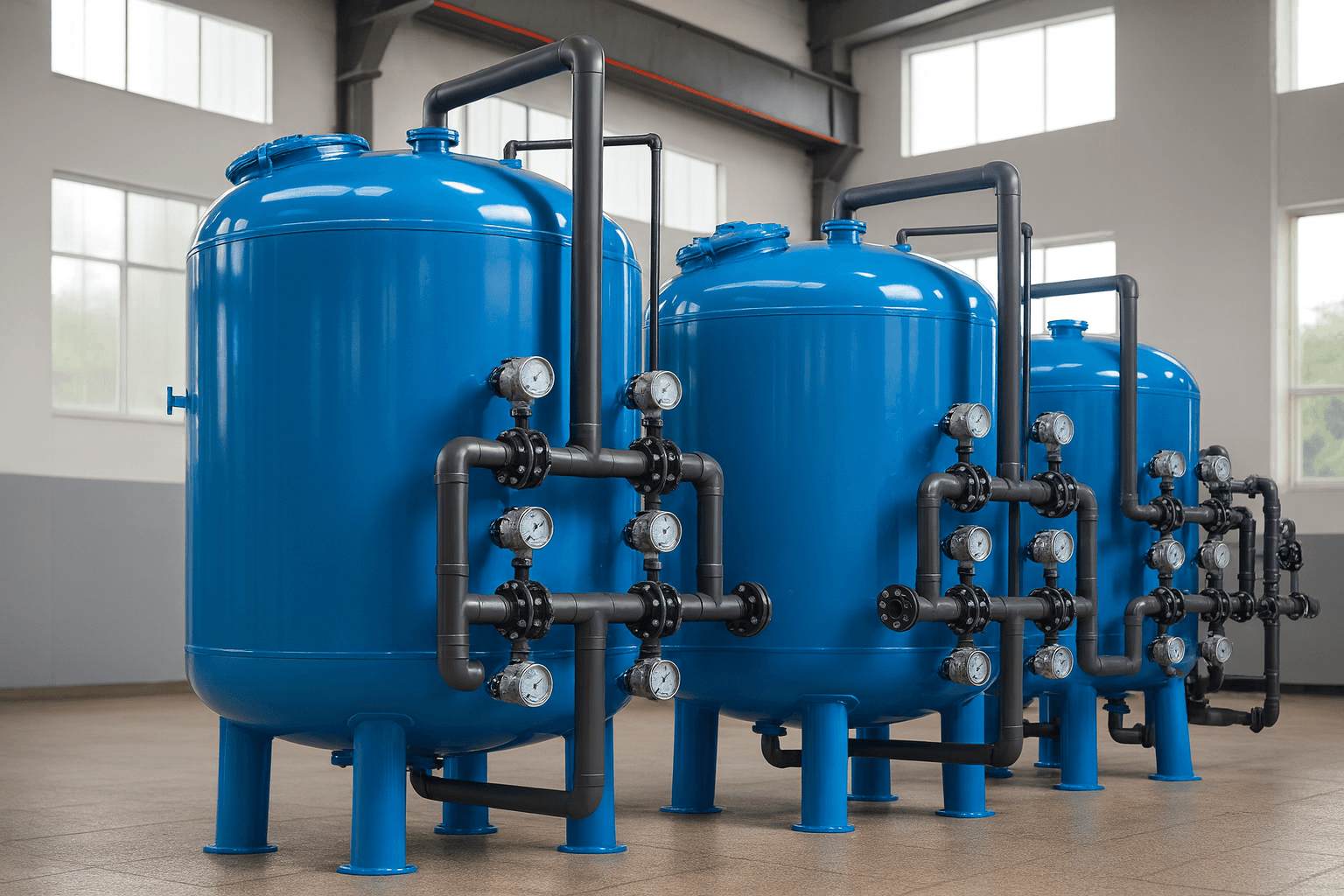

Water Softening Plant Solutions

Compact softening skids that rapidly remove hardness for boilers, cooling towers and food production with plug-and-play installation and low salt consumption.

Custom Tuned

Ion exchange resin systems tuned to your hardness profile

Cost Efficient

Predictable regeneration cycles with low salt consumption

Multi-Purpose

Ideal for boilers, cooling towers, hotels, hospitals, and residences

Ion exchange resin systems tuned to your hardness profile

Service overview

Water softeners remove hardness ions like calcium and magnesium that damage pipelines, boilers, RO membranes, and appliances.

Our ion exchange resin systems are sized to flow rate and hardness levels to deliver soft, scale-free water for industrial, commercial, and residential facilities. Designs focus on effortless regeneration, long resin life, and reduced operational expense.

Deployment Scope

Boiler feed water, Cooling towers, Food & beverage plants, Pharma processing

Key Advantages

Extended equipment life, Reduced scaling & corrosion, Minimal operator intervention, Lower salt usage

Highlights

Plug & play skids • Salt optimized cycles • Dual tank assurance

proof of value

Engineered for performance & scale

Key Features

- Portable skid architecture

- Fast cycle resin beds

- Duel tank redundancy

- Low salt regeneration

- Compact footprint

- Predictive maintenance alerts

Where It Fits

- Boiler feed water

- Cooling towers

- Food & beverage plants

- Pharma processing

- Commercial buildings

Business Wins

- Extended equipment life

- Reduced scaling & corrosion

- Minimal operator intervention

- Lower salt usage

- Rapid serviceability

Launch Checklist

- Plug & play skids

- Salt optimized cycles

- Dual tank assurance

What you get

Deliverables bundled with every deployment

We package each project with tangible artefacts so your engineering, finance, and compliance teams never chase updates. Every deliverable is documented, versioned, and shared in a digital locker for easy recall.

Hardness analytics

Lab tests for Ca/Mg, alkalinity, and iron plus recommended cycle volume for your load profile.

Skid + piping drawings

Compact footprint layouts, brine tank sizing, and tie-in piping schedule for zero-conflict installation.

Twin softener package

Service/reserve vessels with premium resin, multiport valves, flow meters, and safety interlocks.

Regeneration SOP bundle

Step-by-step regeneration guide, brine prep card, checklists, and remote alerts setup.

Engagement playbook

Exactly how we run the mandate

Crystal-clear SLAs keep every stakeholder aligned. From sample collection to AMC handover, we spell out the response times, documentation, and escalation layers in writing.

Kickoff Sprint

Water sample pickup plus utility audit completed inside 3 business days.

Deployment Window

2–4 week fabrication and installation with zero downtime changeover.

Compliance Assurance

Performance verification on treated hardness (<5 ppm) with documentation for QA teams.

Support Model

Quarterly health checks, resin replacement planning, and salt optimization advisory.

delivery blueprint

How your project comes alive

Hardness profiling

Hardness profiling

Capacity & resin sizing

Capacity & resin sizing

Skid fabrication

Skid fabrication

On-site hook-up

On-site hook-up

Performance validation

Performance validation

Service handover

Service handover

live installs

Snapshots from recent deployments

Click to view full size

Common Questions

Frequently Asked Questions

Water softeners use ion exchange resins to replace calcium and magnesium ions (hardness) with sodium ions, preventing scale formation in pipes and equipment.

Ready to Get Started?

Contact us today for a free consultation and customized solution for your environmental needs.

%20water%20treatment%20plant.jpg&w=3840&q=75)